OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

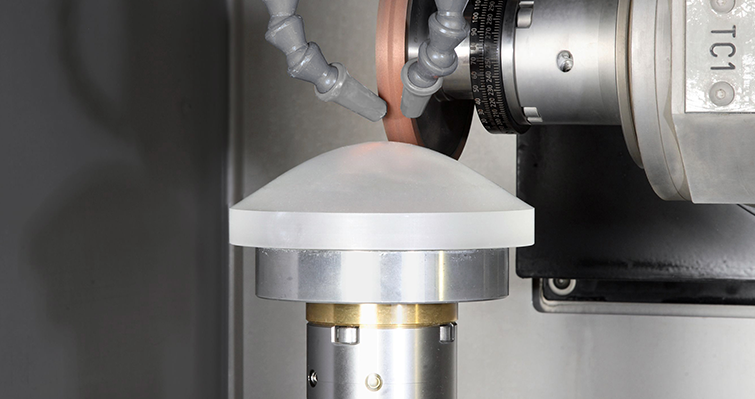

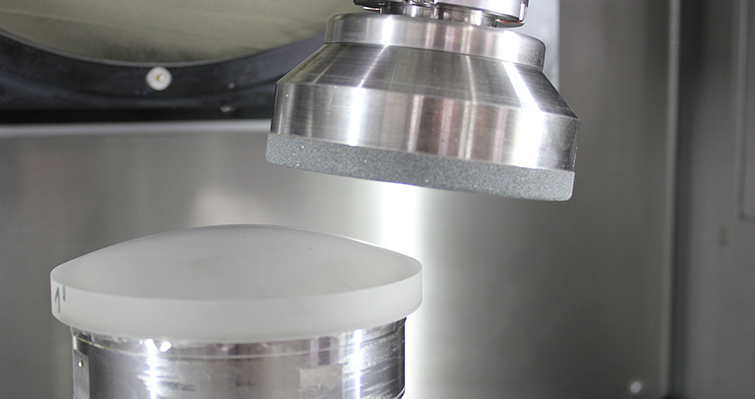

The new compact optical processing center MCG 150 CNC is one of the latest processing centers made by OptoTech. Whatever you want to produce, whether aspheres, spheres, edging, prisms, cylinders. 3D-optics or drilling holes, the MCG 150 is the perfect machine for these tasks. Up to five CNC axes and an innovative tool concept grant the requested flexibility.

Contact request

Machine Options:

Software Options:

Sandusweg 2-4, 35435 Wettenberg, Deutschland