OptoTech Optikmaschinen GmbH

Sandusweg 2-4, 35435 Wettenberg, Deutschland

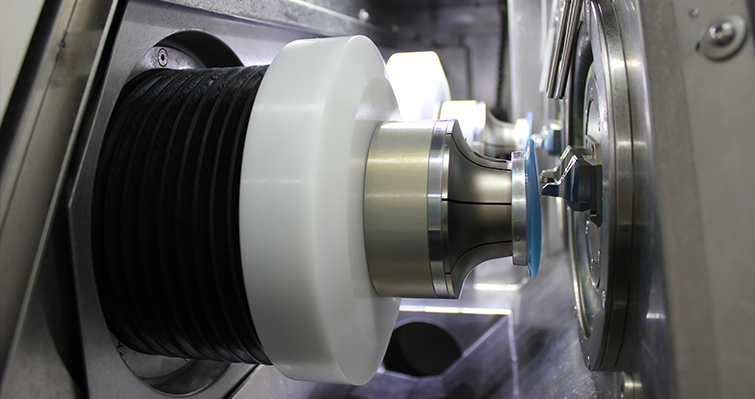

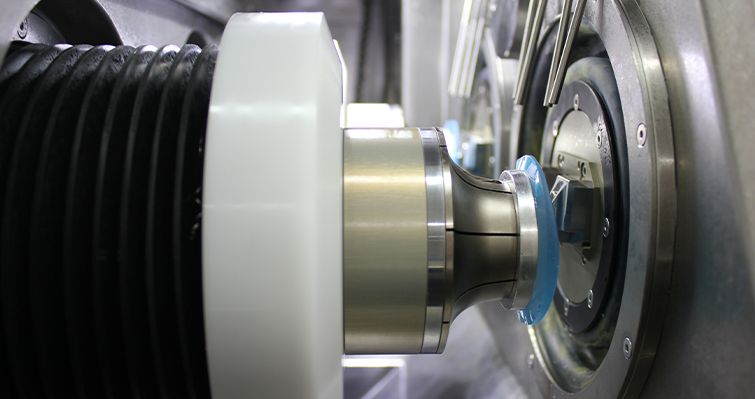

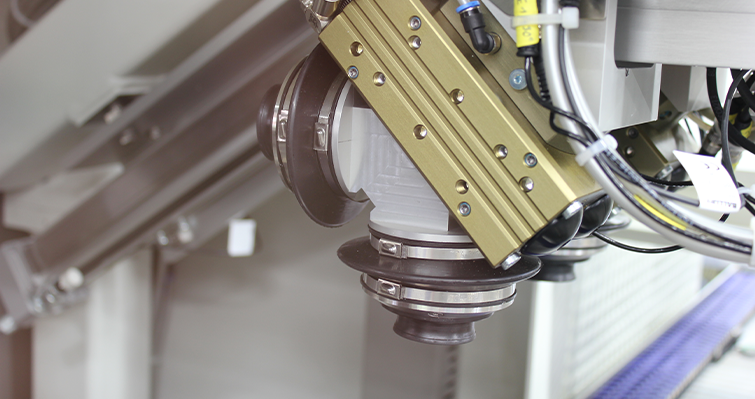

The new digital surfacing-turning machine FLASH Twin-A is an enhancement of our tried and tested FLASH series. Due to the usage of 2 Fast Tools, the FLASH Twin-A is able to simultaneously process 2 freeform lenses. Considerably increased speed of the tool spindles, combined with a high-class precision ball bearing, leads to significant improvements in quality and quantity. It is the ideal complement to our ESM Twin-A.

Contact request

Sandusweg 2-4, 35435 Wettenberg, Deutschland